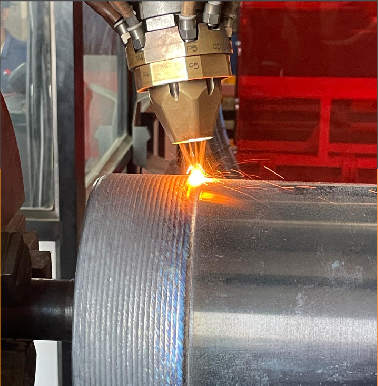

ENHANCED DURABILITY

Increases the wear resistance of ROT roll, extending their lifespan.

Reduces downtime and maintenance frequency.

IMPROVED PERFORMANCE:

Maintains consistent quality and performance under high-stress conditions.

Provides superior resistance to abrasion, corrosion, and thermal fatigue.

PRECISION AND QUALITY:

Achieves precede, uniform coatings with minimal dilution and defects.

Enhances surface properties, resulting in better product quality.

VERSATILITY :

Suitable for various roll materials and sizes.

Customization cladding materials to meet specific operational requirements.

COST EFFICIENCY

Lowers long-term operational costs by reducing the need for frequent replacements.

Minimizes production losses due to fewer roll changes and repairs.

1. Nickel-Based Alloys: Inconel, Hastelloy, Stellite, NiCrBSi

2. Cobalt-Based Alloys: Stellite

3. Iron-Based Alloys: Stainless steels (309L, 316L, 410),tool steels, cast iron.

4.Tungsten Carbides

5.Chromium Carbides

6.Vanadium Carbides

Benefits of Laser Cladding Process

- Metallurgical Bonding

- Minimal Heat Affected Zone (HAZ)

- Reduced Dilution

- High Hardness

- Improved Wear Resistance

- Enhanced Corrosion Resistance

- Thermal Stability

- Improved Surface Properties